Philadelphia continues to grow upward. In 2025, dozens of high-rise projects transform the city skyline. Post-tensioned concrete design in Philadelphia plays a key role. It enables builders to construct taller, stronger structures more efficiently.

Developers face tight schedules and rising costs. This technology helps them deliver projects on time. It also meets strict building codes. Many new towers rely on it for structural integrity.

Philadelphia’s High-Rise Boom in 2025

The city sees robust development activity. Center City and University City lead the way. Over 60 major projects are completed, under construction, or planned.

Residential units dominate. Yet commercial and mixed-use towers rise quickly. These buildings need innovative solutions.

Key Projects Shaping the Skyline

Projects like The Mark at 3615 Chestnut Street stand out. This 34-story tower reaches 414 feet. It features modern apartments in University City.

Other developments include new office spaces and residential high-rises. Chubb’s headquarters adds to the mix. These structures demand advanced concrete systems.

Builders choose materials that handle height and loads. Post-tensioned systems fit perfectly here.

What Is Post-Tensioned Concrete Design?

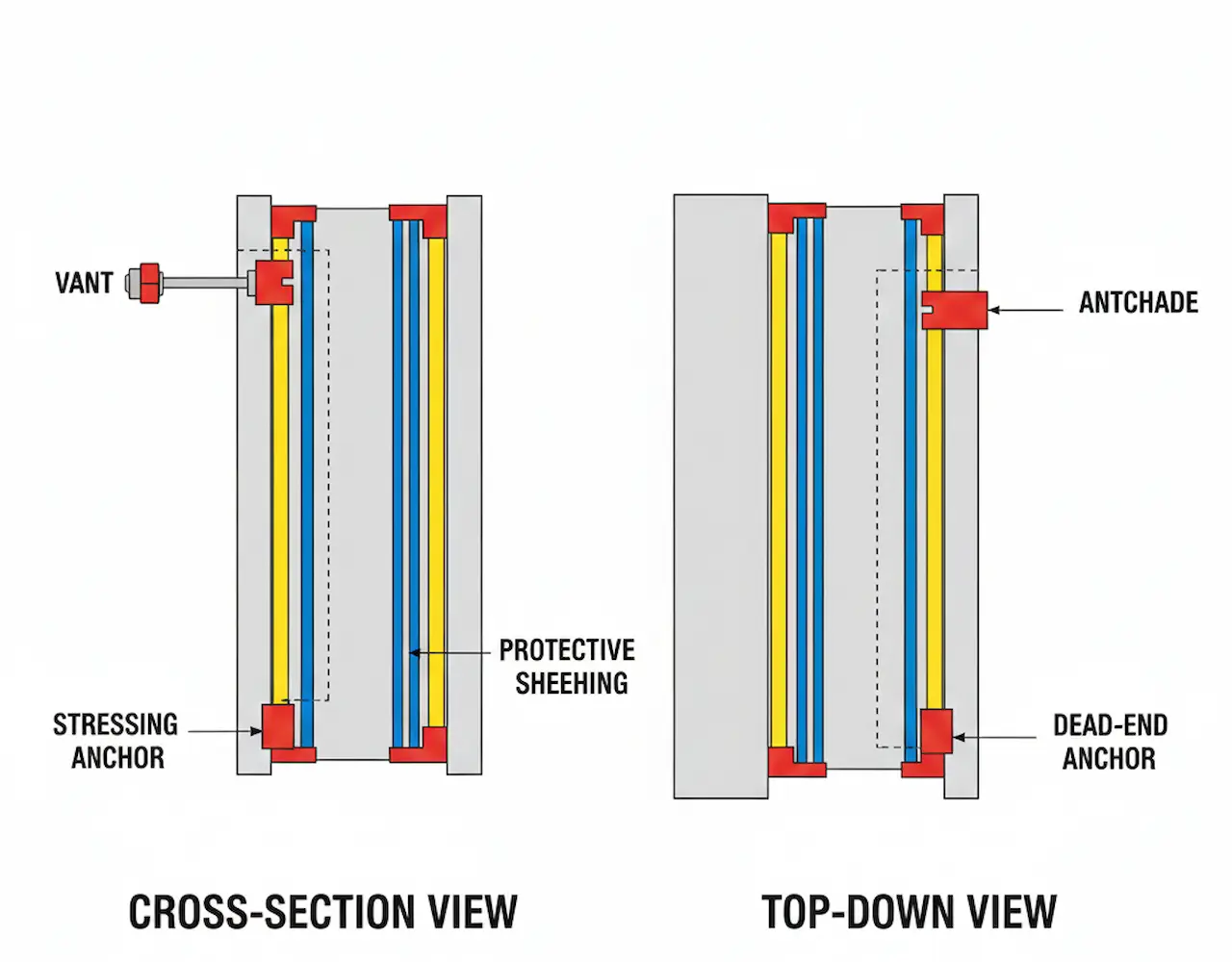

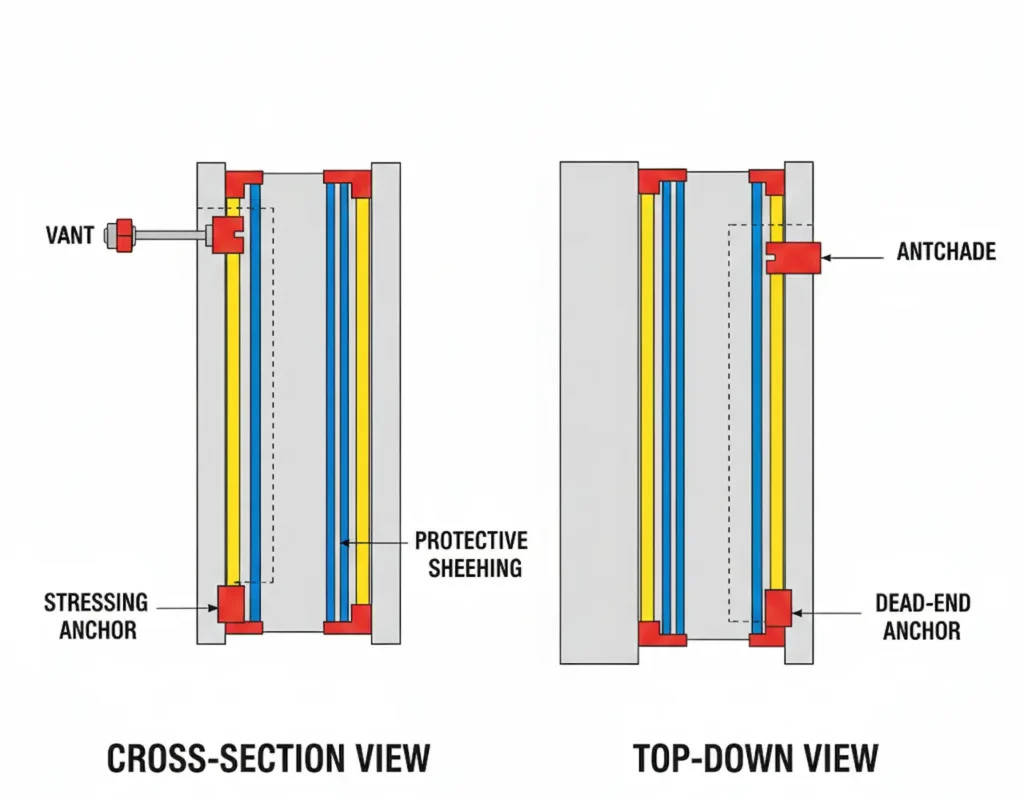

Post-tensioned concrete strengthens slabs after pouring. High-strength steel tendons run through the concrete.

Workers place cables in ducts first. Concrete hardens around them. Then, they pull the cables tight.

This creates compression. It counters tension from loads.

The Post-Tensioning Process Explained

The process starts with formwork. Tendons go in specific patterns.

Concrete pours and cures. Jacks stress the tendons next.

Anchors lock the tension in place. Some systems grout ducts for bonding.

Anchor Installation and Stressing

Anchors hold everything secure. Proper installation prevents issues.

Stressing happens in stages. Engineers monitor forces closely.

Safety remains top priority during this phase.

Advantages of Post-Tensioned Concrete in High-Rise Construction

This method offers clear benefits. Thinner slabs save space.

Builders add more floors without extra height. Foundations carry less weight.

Thinner Slabs and Longer Spans

Slabs stay slim yet strong. Spans reach farther between columns.

Open floor plans become possible. Tenants enjoy flexible spaces.

Reduced Cracking and Enhanced Durability

Compression fights cracks. Structures last longer.

They resist seismic forces better. Fire resistance improves too.

Post-Tensioned Slab vs. RC Slab: Cost and Performance Comparison

Traditional reinforced concrete uses more material. Post-tensioned slabs often cost less overall.

Studies show savings in steel and concrete volume. Long-term maintenance drops.

Performance edges out RC in deflection control. High-rises benefit most.

Why Philadelphia Developers Choose Post-Tensioned Systems

Local conditions favor this approach. Soil types vary across the city.

Projects need resilience. Efficiency drives decisions.

Labor shortages push innovation. Skilled teams handle complex work.

Challenges and Best Practices

Specialized knowledge is essential. Errors in stressing cause problems.

Regular inspections ensure quality. Follow ACI and PTI guidelines.

Plan for future modifications carefully. Tendons limit some changes.

The Future of Post-Tensioned Concrete in Philly

Trends point to wider use. Sustainability gains importance.

Lighter structures reduce carbon footprints. New codes support adoption.

Philadelphia’s growth continues. This technology will shape tomorrow’s towers.

Conclusion:

Build Stronger with Expert Staffing Support

Post-tensioned concrete powers Philadelphia’s ambitious projects. It delivers efficiency, strength, and cost savings.

At PhillyTradeExperts, we connect you with skilled concrete professionals. Our team understands post-tensioning demands.

We provide reliable staffing for your high-rise needs. Contact us today at [email protected] or call (215) 555-1234. Let us help you build the future safely and on schedule.

FAQs

Post-tensioned concrete uses high-strength cables tensioned after pouring. It creates stronger, thinner slabs ideal for Philadelphia’s high-rises.

Post-tensioned slabs often save 15-25% on materials. They reduce steel and concrete needs while improving performance.

It allows taller buildings with open spaces. Projects like The Mark benefit from lighter weight and faster construction.

Key benefits include reduced cracking, longer spans, and better seismic resistance. It also lowers overall building height.

Yes. The compression enhances durability. Structures perform well under lateral forces.